Precision Taps

Swanson provides quality taps for every purpose. We bring three generations of tap manufacturing experience to our products. Our attention to tool geometry and heat treating ensure longer tap life. Your applications will benefit from our 100% Total Thread Quality Control. Continuous in-process inspection and gaging are standard practice at Swanson Tool Manufacturing. Properly designed for your application, our taps make the difficult easy and reduce your cost per hole.

Swanson provides taps specially designed for each of the following materials:

- Medium alloy steels (4140, 5280)

- Titanium

- Stainless steel and high alloy steels

- Aluminum and similar nonferrous materials with long stringy chips

- Aircraft grade aluminun alloys and other nonferrous metals with short stringy chips

- Case hardening steels

- Cast iron

- Taps also available in high speed steel and premium steel

All taps are available in inch and metric, left-hand and right-hand.

Conduit

- Per DIN #40430

- “PG” series

- 80° included angle

Coolant-Fed

- Ideal for blind holes

- Increases tool life

- Increases production

Spiral Flute

- Ideal for blind holes

- Low/medium or high helix

- Pulls chips from hole

Nib

- Ideal for nut tapping

- Solid/threaded shanks

- All styles available

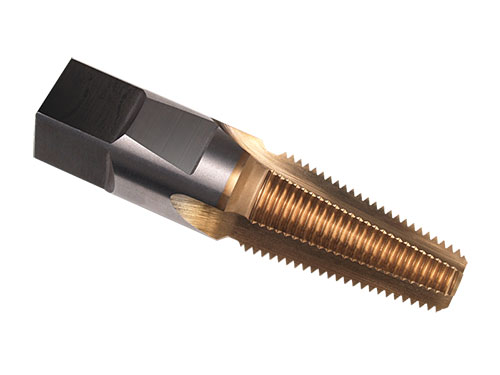

Pipe

- Tapered or straight

- Interrupted thread

- Special projections

- Straight or spiral flute

- Extensions

Acme

- Regular or tandem style

- Straight or spiral flute

- Special designs for part

Design Specials

- Multiple starts

- Piloted taps

- Shell taps

- Extension taps

Thread Forming

- Multiple starts

- Piloted taps

- Shell taps

- Extension taps

Swanson CNC Special Premium Steel Taps

These CNC designs reduce chip buildup in holes. They feature special reliefs for freer cutting and have a higher hardness and toughness.

Spiral Point

- For thru hole applications

- Pushes chips out of hole

Spiral Flute

- For blind hole applications

- Pulls chips out of hole